Ventilation ducts - Panattoni

Panattoni Park Zgorzelec - We successfully carried out insulation work on the cooling units in an impressive warehouse building with an area of 30,000 m².

Our task included the installation of 100 mm thick insulation, followed by the installation of a protective jacket made of 0.7 mm thick galvanized sheet metal.

The entire job involved 11 air conditioning units and covered an impressive total area of almost 1,400 m². We are proud to have contributed to this outstanding infrastructure!

Flue gas desulphurization plant - Jaworzno

On the construction site of a newly built block in a coal-fired power station, we successfully insulated the absorber, which is an essential component of the flue gas desulphurization system.

As part of this work, precise welding work was carried out to securely fasten the elements of the protective jacket support structure to the walls of the absorber. Comprehensive corrosion protection was implemented to ensure the longevity of the structure.

The next step involved the installation of 50 mm thick rock wool insulation, followed by the application of two layers of insulation with a total thickness of 100 mm. The final step was the installation of the protective sheathing, in this case made of high-quality trapezoidal sheet metal in an attractive RAL color. All the necessary covers and seals were carefully installed.

The total area of the work carried out amounted to an impressive 1860 m².

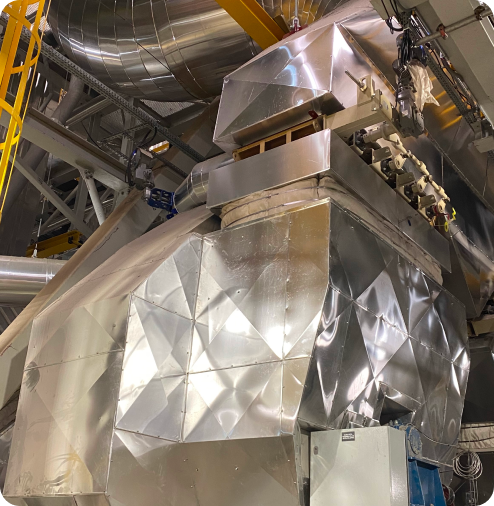

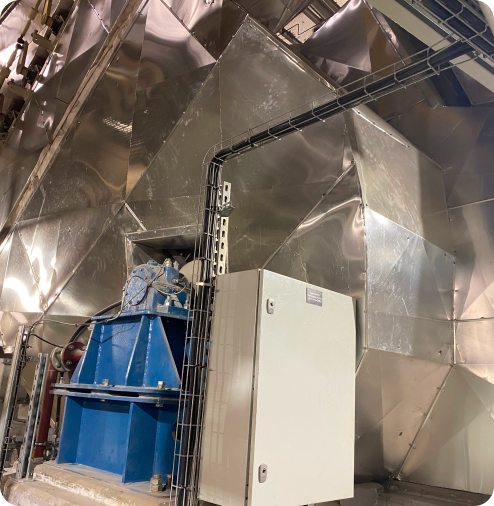

Sound insulation of the flue gas duct fan

We successfully implemented the sound insulation of a large flue gas fan in a power plant for our valued customer. The soundproofing of the fan involved the careful installation of five layers of insulation, each 60 mm thick.

Before starting our insulation work, we precisely welded the supporting structure of the insulation and the sheet metal jacket, which we manufactured from high-quality aluminum sheet.

In total, the area of our work on the flue gas fan and the flue ducts leading to and from the fan covered an impressive 1850 m².

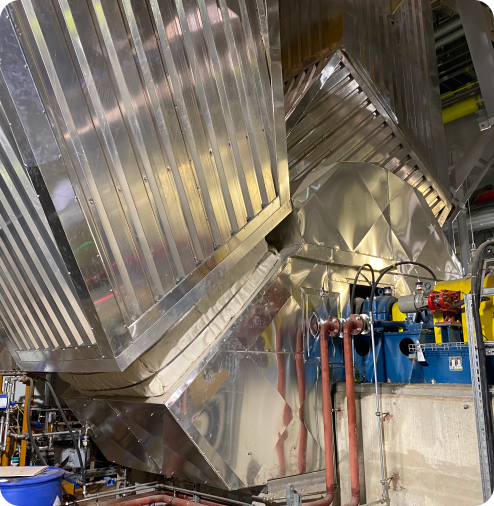

Fans on the power plant site

The project involved the comprehensive sound insulation of six fans at the power plant site. In our production facility, the supporting structure for the metal protective jacket was carefully prepared, including the metal sheets for the protective jacket. This construction was precisely welded to the fans and also received extensive corrosion protection work.

For effective sound insulation of the fans, we installed a total of five layers of Rockwool insulation, each 60 mm thick. Once the insulation was in place, the previously welded construction was covered with a protective sheet metal jacket. We also carried out all the necessary sealing work to ensure the highest quality and durability.

In total, the project consists of six fan units covering an impressive area of almost 1200 m².

Let's talk

Are you interested in technical insulation? We will be happy to help you.

Let's get started

Ready for innovative solutions?

Let's get started together and take your projects to the next level!